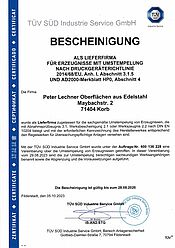

TÜV restamping certificate renewed

Every year, renewals are necessary. This year we have also had one of our important certificates for our services renewed. After thorough training, instruction and testing by TÜV Süd, we now have 6 authorised specialists who meet the requirements for the TÜV restamping certificate. An absolutely broadly positioned team is now available to our customers. Thanks to our well introduced and also motivated team and very good equipment, we are also able to realise the TÜV restamping for small dimensions.

Inside grinded round tubes surface Ra 0.2my

To ensure that internally grinded stainless steel tubes arrive safely, each round tube is protected at each opening with laser foil. The tubes are well protected in the area where the forklift tines grip. Another important factor is that the bundle does not slip as it would if it were plastic foil around of the bundle. Of course, the environmental idea is very important and purposeful

Flatbar 45x12mm grade 304L

The transitions from the broad side to the material thickness are made even sharper by grinding. Due to the high-quality grinding with our grinding machines, the material planes move closer together, resulting in a sharp-edged flatbar steel. All grinded stainless steel flat bars and profiles receive the laser foil as a proven scratch protection with the imprint of dimension, batch and materialgrade.

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/spot-nickel-30d.gif)