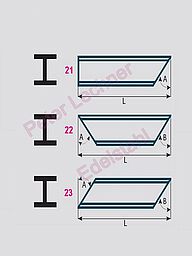

Cutting diagram for stainless steel profiles. The miter details always refer to the cutting scheme.

Coating with Lechner protection film gives you considerable advantages when sawing. In this movie you will see the advantages of automatic abetment. The time savings and the certainty that the materials are cut at the right angle and reach your workbench just in time relieve your production line and secure additional orders for you.

Ask us, the Lechner stainless steel team for saw cuts.

Cutting options for stainless steel profiles:

• Cross section Ø / = 10 - 300 mm

• Length = 10 - 5600 mm on both sides

• Length = 10 - 6000 mm one-sided

• Miter left and right = 135 ° - 20 °angle tolerance for all miter cuts ± 1 degreeThe miter details always refer to the cutting scheme.

Sawing stainless steel tips, tricks and hacks

Here you can see very impressively the perfect end result when the tool, cutting parameters and overall operation of the saw match. The narrow material thickness clearly shows that the saw feed and the countersink match precisely. When sawing stainless steel profiles, it is important to observe the important safety features. This includes not only gloves and safety goggles. We are happy to take care of this for you and produce fixed lengths of stainless steel profiles with delivery directly to your workbench.

Tips for sawing stainless steel profiles:

- Use a precisely dimensioned sketch/drawing, especially for mitre cuts

- Clamp profiles firmly, avoid scratches by using aluminium clamping jaws or protect polished surfaces with our laser foil

- leave a small saw burr, as this can be used as filler material for further skilled welding.

- Blow out the sawdust from hollow profiles

- Protect profiles against scratches with laser foil. Masking tape is not suitable.

- If there is any adhesive residue from the protective film, simply remove with acetone or white spirit

- Always saw off the bevelled edge of sanded profiles.

- Do not cool with emulsion or water, but saw with spray oil. This has the safety advantage that the workshop floor is not dripped with water and the carry-over and contamination by rust is prevented.

- Protect profiles against scratches with laser foil. Masking tape is not suitable.

- If there is any adhesive residue from the protective film, simply remove with acetone or white spirit

- Always saw off the bevelled edge of polished profiles.

- Do not cool with emulsion or water, but saw with spray oil. This has the safety advantage that the workshop floor is not dripped with water and the carry-over and contamination by rust is prevented.

- Always label the remaining piece with the dimensions of the material and remaining length. This saves time in the manual warehouse and during stocktaking.

- When making a 90°degree straight cut, ensure that there are only a few saw teeth in the profile.

- NEVER use an angle grinder!